As a leading growth economy, India has to play its part in adopting clean solutions while decarbonizing its ecosystem. That’s why PV Evolution Labs (PVEL) is working to drive the deployment of reliable solar power and energy storage solutions in India.

The two biggest opportunities for mitigating our climate impact are electric generation and transportation. India has ambitious targets for renewable energy deployment and electric vehicle (EV) adoption. Solar energy is a large portion of the 450 GW renewables target by 2030 (Source: The Economic Times). Various states have already announced 100% EV adoption across categories.

These massive demand side initiatives are also supported by strong supply side developments. In June 2019, India was producing the world’s cheapest solar power (Source: World Economic Forum). Lithium-Ion battery prices have fallen from $1000 / kWh to ~ $150 / kWh in the past decade resulting in faster adoption of EVs. The growth in both these sectors are mega trends that we will witness during the next few decades with an outlay of billions of dollars of capital to make that growth happen.

As the market grows multi-fold, quality and reliability of equipment becomes imperative. PVEL is the leading independent lab for the downstream solar and energy storage industry and has accumulated more than a decade of measured reliability and performance data for PV and storage equipment.

PVEL provides developers, investors and asset owners with a suite of technical services for mitigating risk, optimizing financing and improving system performance throughout the project lifecycle. Our annual publication, the PV Module Reliability Scorecard, is widely popular within the solar industry and shares the benchmarked performance data of the top PV manufacturers. As India grows, PVEL is excited to play a larger role within the local ecosystem. Below are some key areas of consideration in the Indian context.

1. Life Cycle Management

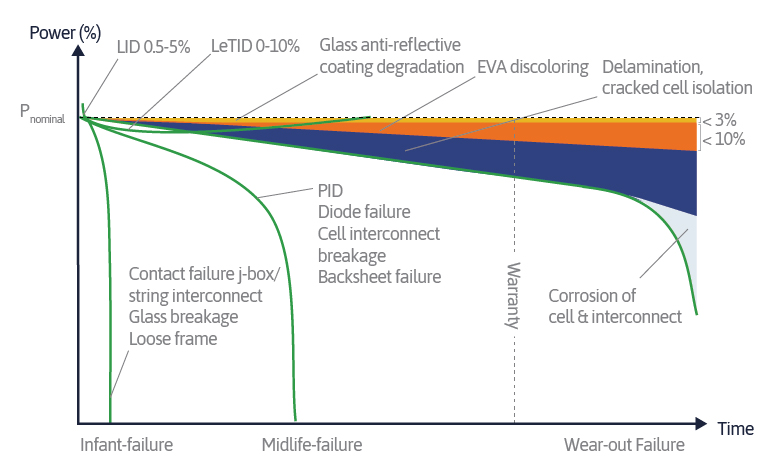

Large-scale solar adoption in India started in 2010. The projects are yet to see a 25-year cycle. A solar panel has multiple failure points across its lifetime. See figure below. Our stringent Product Qualification Program (PQP) does accelerated testing to simulate 25-year field conditions through a set of rigorous tests.

We share this information with our downstream partners – investors, asset owners, developers and other companies on the buy-side of equipment transactions – at no charge to bring the most accurate data and increase accountability in the ecosystem.

Source: IEA PVPS 2014; LETID AND backsheet failure added by PVEL, 2019

2. Specific weather conditions

In our 2021 PV Module Reliability Scorecard (click here to download), we highlight specific issues related to heat, humidity, and temperature fluctuations which are common weather conditions across India. PVEL conducts specific tests that pertain to these conditions. These tests are Thermal Cycling, Damp Heat, LeTID Sensitivity and the Mechanical Stress Sequence.

“LETID affects advanced multicrystalline and monocrystalline cell architectures. It has been shown to materialize when cells reach temperatures over 40°C while operating, which not only occurs in hot environments but also in temperate regions during high irradiance. Degradation eventually stabilizes and can recover over time, but regeneration rates vary.”

Source: 2021 PVEL PV Module Reliability Scorecard

3. Race for scale and technology obsolescence

The large-scale utility bids have seen tariffs fall from Rs. 4.63 / kWh (~ $0.063) in end 2015 to Rs. 1.99 / kWh (~$0.027) in December 2020. With competition and aggressive bidding, developers are trying to optimize equipment to ensure maximum yield from their plants. There is a move away from poly to mono PERC and glass//glass to ensure maximum output. With newer technologies coming into the fray, reliability becomes increasingly critical.

4. Storage – the next frontier

Energy storage has two primary use cases, first for stationary storage and second for mobility. In addition to our solar module and inverter testing, PVEL has an Energy Storage Product Qualification Program where we test for charge / discharge States, temperature, state of charge map, throughput and shelf life.

Batteries alone are 35-50% of the cost of an electric vehicle. Assessing the residual value of a battery is an important driver for financing EVs. Our accelerated testing program coupled with software testing gives deep insights on the useful life. Furthermore, Indian driving patterns, road and weather conditions also call for testing various other battery chemistries in the near term.

5. Supporting Indian manufacturers

Over the years, the support for domestic manufacturers in India has resulted in a few players building significant scale to support domestic demand and export to other nations. As Indian solar and storage manufacturers start competing at a global scale, the Product Qualification Program becomes an important tool for manufacturers to stand out from the rest.

Over the last 11 years, PVEL has developed unique lab facilities, testing methods and innovative tools for the solar and storage industry. We recently partnered with the Kiwa Group to further expand our geographic footprint. Our aim is to connect OEMs and the downstream market, the users of technology, to drive the expansion of reliable renewable power for decades to come.

For more information on the PQP process and our plans in India, please contact Sishir Garemella.

Sishir Garemella is PVEL’s representative on the ground in India.