Meet Nick Price, one of PVEL’s summer interns

My experience working at PVEL, as a young engineering student, in the context of climate change and renewable energy

Joining the PVEL team earlier this year, I wasn’t sure what to expect. Having only briefly visited their labs a few summers ago and having had little insight into the ins and outs of the work they do, it was my desire to gain experience and a deeper understanding of the PV industry that drove me to reach out to the PVEL team. As only a second-year STEM student, I haven’t had much opportunity to do work that is relevant to my interests and also allows me to apply the skills I have learned at university. PVEL was a great chance for me to do this.

During the internship, I was assigned various projects by Max Macpherson, an associate project manager. She was incredibly helpful the entire time. Whether it be answering my many questions (always immediately, despite the time-zone difference), setting me work to do or just checking-in, she was consistently enthusiastic and supportive. Thanks Max!

Through the internship, I helped the PVEL team increase the efficiency of access to their reports, created an easy-to-read events calendar, uploaded older bills of materials (BOM) datasheets to the PVEL Portal and researched recent industry news. All of these jobs should hopefully allow PVEL to run more smoothly and spend less time focusing on smaller details.

However, most of my time at PVEL was spent assisting with a new product called the Premium Partner Dashboard. This is a huge database that subscribers can access that includes test results, cell characteristics (module width, backsheet colour, etc.) and PVEL reports associated with different BOMs. It was a really useful way for me to gain an insight into how a company like PVEL operates and deepen my understanding of PV modules and how they are tested in the PVEL Product Qualification Program.

During the several projects I worked on, the parts I found most enjoyable were when I was able to dig deep into the PVEL datasets and really start seeing how the PV market has changed in the past eight years or so. I looked at how module characteristics, cell technology and module manufacturers have changed since 2013, and also looked for links between modules that had particularly poor test results. For example, was there a specific backsheet vendor that they had in common? I also found it really interesting finding insights in the trends I was able to observe.

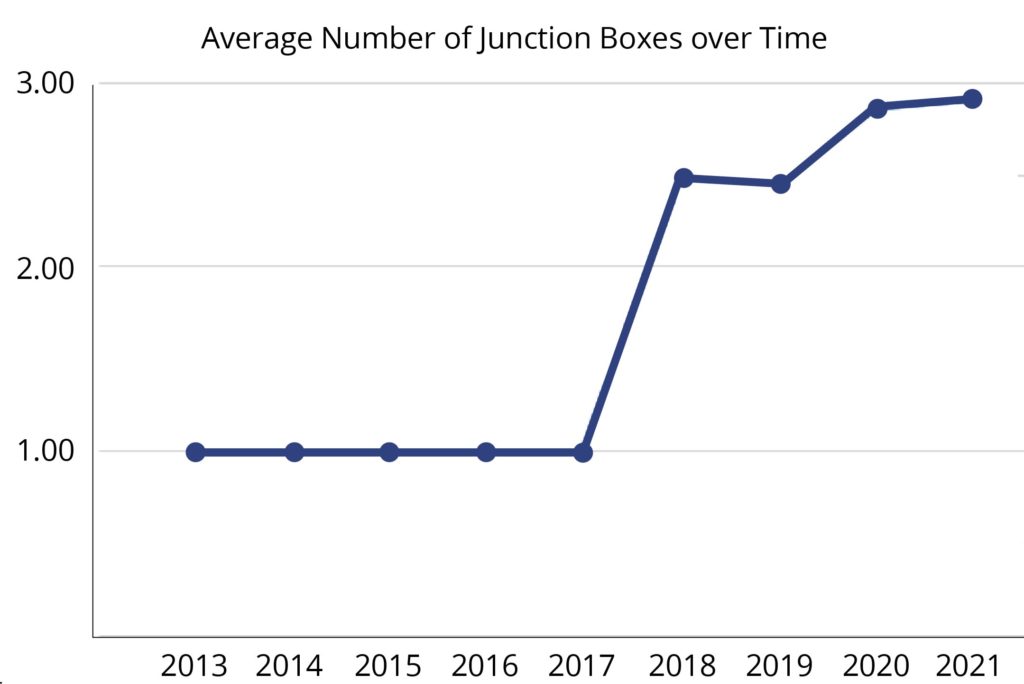

Take the average number of junction boxes present on a module. In Figure 1 below, it is clear to see that there has been an increase in the average number of junction boxes; up to 2017 it seems that all modules had one, and in 2018 there is a big jump followed by what looks like a steady increase in junction boxes. By 2021 the majority of modules have three, with some even having four.

Figure 1: The average number of junction boxes per module observed in modules submitted for testing began to jump to 3 in 2018.

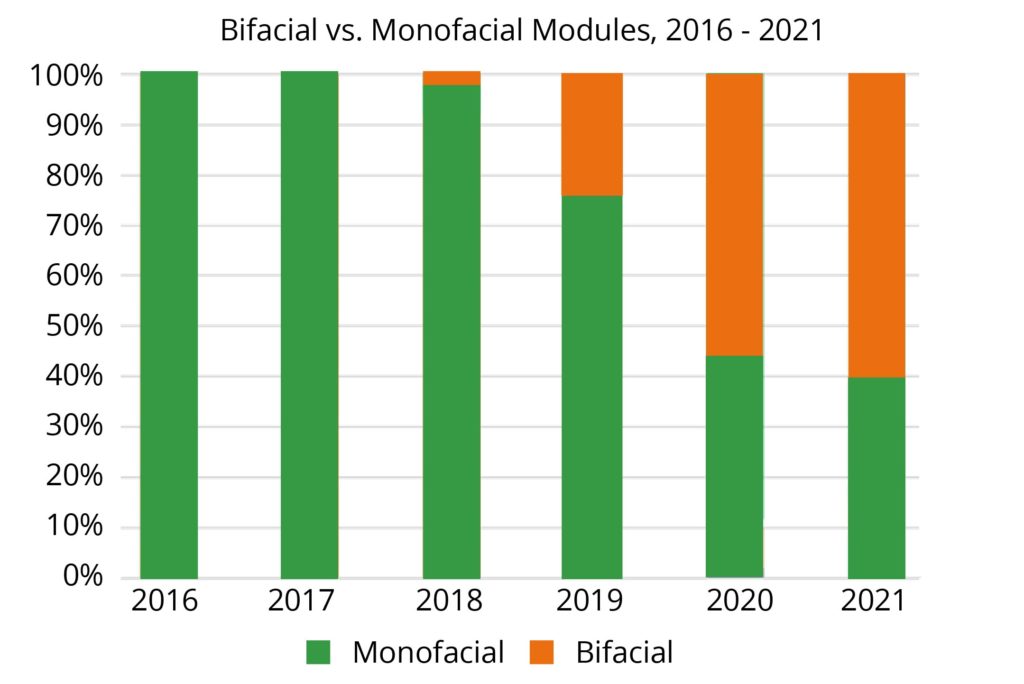

The reason for this increase, I thought, must be connected to the rise in popularity of bifacial modules; as the industry tended towards bifacial modules, having one large junction box on the back of the module no longer made sense, and thus having more, smaller junction boxes was the solution to that problem. Figure 2 shows the proportion of modules that are bifacial since 2016 – the first instance of bifaciality (in the PVEL dataset, at least) is also seen in 2018!

Figure 2: Since 2016, there has been a rapid increase in the number of bifacial modules submitted for testing.

My time at PVEL has been extremely helpful. I was able to get practice handling and manipulating large datasets, understand the work that goes into making a testing lab such as PVEL tick, and most usefully, I was able to gain experience working in the renewable energy sector, hopefully helping me to pursue my goals of working in PV/battery tech.

The main factor that kept me motivated this summer was the fact that the work PVEL does helps to make a real, positive change to the world. I have always wanted the work I end up doing to mean something – whether that be helping people or helping society – and working at a company with people who share the same goals was really inspiring.

The comprehensive testing and data analysis that is done at PVEL helps drive the PV market in a positive direction. The work allows module manufacturers to properly understand the changes they may need to make in order to keep up with consumer demand, government quotas or even simply competitors. I am glad to have been a part of the PVEL team this summer and I hope that the work I did was as useful to them as it was for me!

About the Author

Nick Price is currently pursuing an MS in Physical Chemistry at Imperial College London. Click here to connect with him on LinkedIn.