Introduction

The function of a Rapid Shutdown device (RSD) is to deenergize rooftop solar power systems in the event of a fire thus protecting first responders from exposure to live wires. Fire on a rooftop solar project is an imminent risk anywhere in the world but it is in the US that RSD is now mandated by National Electricity Code (NEC). Over the years, Module Level Power Electronics (MLPE) technology has gained substantial market share in the US rooftop solar segment and while many of the leading MLPE players already have inbuilt RSD capabilities within their devices , for the rest of the playfield RSDs are new. In many ways, the RSD market is in its nascent stage. Firstly, RSD penetration has been only in the last four to five years hence there are limited number of players in this space. Secondly, there is not much historical track record in terms of equipment reliability and warranty enforcement.

Field Failures

At PV Evolution Labs (PVEL), we are constantly speaking to downstream players and creating reliability testing programs that simulate most pressing field failures. Across 2021, we spoke to numerous players about RSD efficacy. Ironically, the very device that is supposed to deenergize the solar system in the event of the fire can sometimes be the cause of smoke and fire in itself.

RSDs can also interfere with the detection of arc-faults by the inverter. RSDs receive a signal from a transmitter using Power Line Communication (PLC) over the DC line. This PLC signal adds ‘noise’ to the DC line, which can impact the inverter’s ability to detect arc faults. Adding such a signal emitting device on the DC line introduces risky complexities to a vital operation of a PV system and makes it imperative to test the specific combination of RSD and inverter to determine that arc-fault detection is unhindered.

PVEL’s RSD Testing

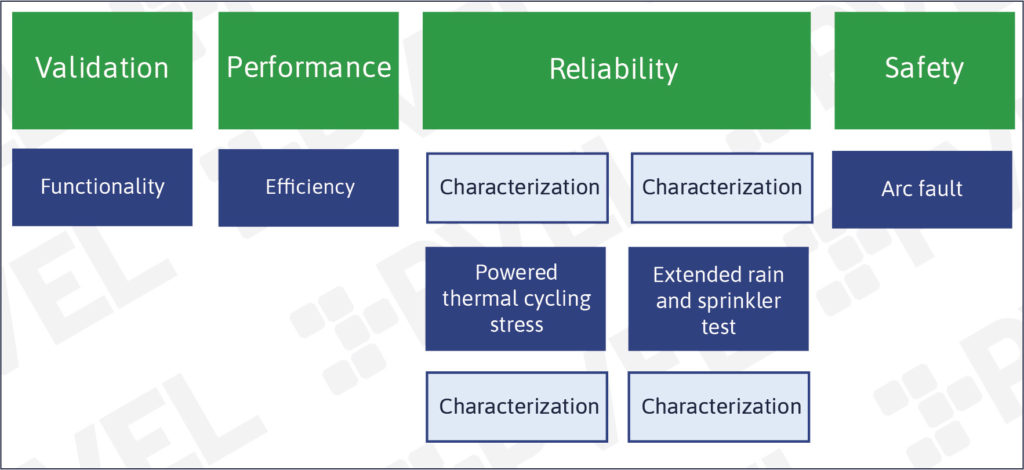

PVEL’s RSD evaluation program is a set of lab and field tests over a period of 8 – 10 weeks. The tests focus on validation, performance, reliability and safety aspects of the device. Picture 1 below shows the detailed testing legs while Picture 2 shows the test rig for PVEL’s extended rain and sprinkler test protocol.

Picture 1: The PVEL RSD Evaluation Program

Picture 2: PVEL conducts extended rain and sprinkler testing for RSDs at our field testbed at PVUSA.

Next Steps

We suggest two approaches to testing. First, technical qualification of a new product or supplier. Second, ongoing testing to verify batch level quality i.e., test a sample for every 1,000 units ordered. Its imperative to check that the RSD product is reliable in itself and that is it reliably compatible with a specific inverter.

For more information on RSD testing, please reach out to me at sishir.garemella@pvel.com