Solar power plant underperformance directly translates to lost revenue for asset owners. But when does it justify additional investments in O&M? Allowances for lower-than-expected energy yield are usually built into financial models, but they vary by project – for some solar power plants, just a 3% loss in production eliminates profits. Others have more leeway. The key for asset owners is to invest in O&M strategies that ultimately pay for themselves in terms of recovered revenue. One example is electroluminescence (EL) imaging in the field.

EL imaging is quickly becoming one of the most important and cost-effective O&M tools available, particularly when asset owners are filing warranty and insurance claims to recoup losses from defective or damaged products. A few examples of these claims include:

- Manufacturing defects

- Transportation and shipping damage

- Damage from improper installation

- Force majeure events such as hurricanes, tornadoes, hail storms, lightning, earthquakes

When issues arise, asset owners (or the insured party filing the claim) have just one chance to document and receive compensation for all of the damage incurred. Problems that are overlooked initially will not be covered under the same incident claim in the future. With EL testing, asset owners can quantify the full extent of damage to PV modules – even when system underperformance due to microcracks is anticipated but has not yet occurred.

Advances in EL Imaging for PV Modules

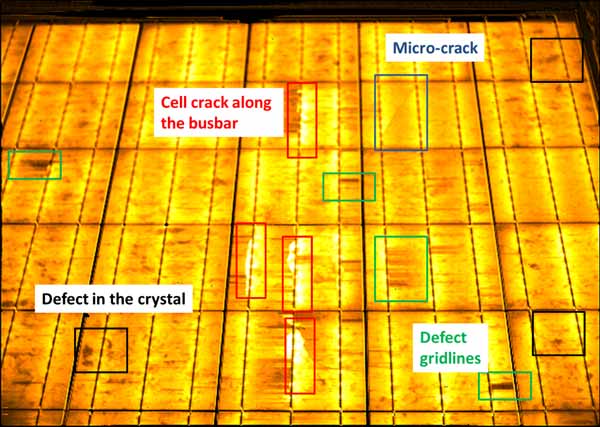

Taking an (EL) image of a PV module is similar to taking an X-ray. EL images reveal defects and microcracks in the inner structures of the solar cells that make up a PV module. EL technology allows asset owners to clearly identify the modules with cell damage that will likely cause underperformance or hot spots in the future.

An EL image reveals defects and microcracks in a PV module

Over the past decade, the practice of EL imaging has advanced dramatically. While this technique was once restricted to highly controlled indoor laboratory environments, it can now be used effectively in the field while the sun is shining. Asset owners no longer have to dismantle installed PV modules to test them remotely – and they don’t need to conduct in-field EL testing during nighttime hours.

Instead, technicians can capture EL images in the field during a regular workday without removing modules from mounting systems. It’s a far simpler process that eliminates module shipping costs and significantly reduces labor costs.

PVEL has utilized a unique field EL camera and testing system designed for daytime operation for more than two years. In that time, we have improved the efficiency of our field EL test protocols by more than 100%. Because of these advances, field EL testing is now more cost-effective than ever before. It’s time for asset owners to leverage this technology to safeguard the financial performance of their solar power plants.

Quantifying Hail Damage with Field EL: A Real-World Example

To illustrate how field EL protects the bottom line of asset owners, let’s walk through a hypothetical example based on real-world projects that PVEL has supported. Imagine you own a 100 MW solar power plant in Colorado that just got hit by a major hail storm – while you don’t know exactly how much damage has occurred, it’s clear that some equipment must be replaced.

(This scenario is becoming more common for PV asset owners. According to a recent study in Nature Climate Change, the size of hail is likely to increase due to climate change, resulting in more destructive storms.)

A PV module with visibly broken glass due to hail.

As an asset owner preparing to file an insurance claim for damaged PV modules, you need to determine the exact number of modules that must be replaced and the cost of replacing them. You visually inspect the 270,000 370W (100MW) modules and find:

- 5% show visible damage and must be replaced – that’s 13,500 PV modules.

- Assuming pricing of $0.35 USD/watt for PV modules and $50/module for labor (including removal of broken equipment, installation of new equipment and recommissioning), your insurance payout is $2.42M USD.

- This insurance payout does not cover business interruption while the site is down.

But what if you didn’t stop at visual inspection when assessing damage? Let’s imagine you’ve seen research that shows that widespread microcracks can occur in sites where only 5% of modules have broken glass. You decide to conduct field EL testing on a statistically significant portion of the array, which shows:

- 20% of the non-visually damaged modules have microcracks and should be replaced – that’s 54,000 modules.

- Your insurance payout is now $9.69M USD – nearly 4x the size of the claim without EL testing.

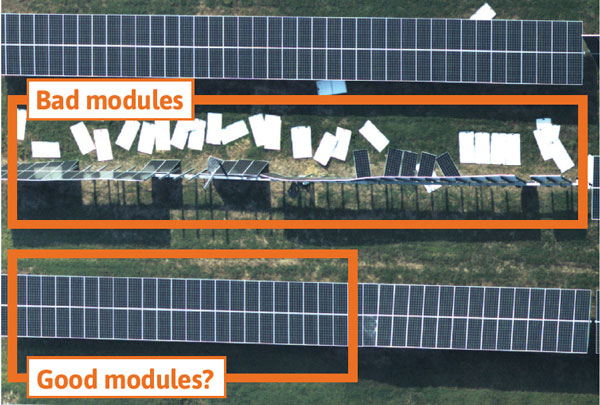

Modules with microcracks may appear to be undamaged during visual inspections. Image source: Heliolytics

In this case – which is similar to other projects PVEL has supported– the cost of field EL testing is covered by insurance, and it enables you to protect yourself from losses due to future underperformance as a result of this incident. In the meantime, either the microcracked modules would be replaced or the money would be held in escrow, while you wait for the power loss or hot spots due to microcracks in the modules to occur. The visibly damaged modules would be replaced right away.

Most importantly, without EL test results, it would not be valid to claim the microcracked PV modules at a later date when the power loss or hot spots are noticeable. If asset owners wait a few years after the incident occurred, their window of opportunity closes: insurance policies are written with a narrow timeframe in which damage from force majeure events can be reported, and asset owners can only submit one claim per event.

Benefits for Asset Owners

Field EL is an O&M strategy that ultimately pays for itself by protecting asset owners from future financial losses and supports comprehensive insurance claims containing detailed evidence of damage.

As an additional safeguard, asset owners can conduct field EL on a statistical sample of PV modules as part of a project’s standard commissioning and acceptance tests to identify unseen transportation and installation damage. The field EL images can be compared with EL images taken in the factory, and then used to support EPC warranty claims.

If an incident occurs once operations are underway, the baseline data captured at commissioning can help clarify the microcracks that occurred because of a natural disaster or other force majeure event – and were not caused by transportation and installation issues.

Importantly, field EL can be combined with other O&M services to further reduce costs. To learn more about combining field EL with aerial inspection and infrared imaging, explore Incident Response, a testing service we developed with Heliolytics to help asset owners address force majeure events.