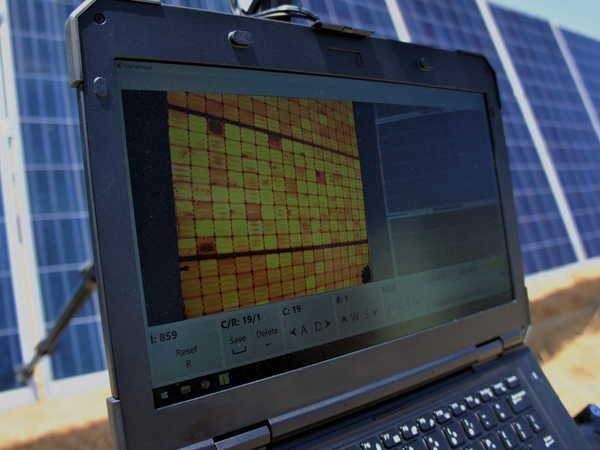

PVEL’s Field electroluminescence (EL) imaging services offer comprehensive solutions for understanding the health of your PV modules, diagnosing solar plant underperformance, and assessing the damage caused by force majeure events. EL images reveal cell-level damage and defects that are otherwise invisible to the human eye.

Establish overall project health and mitigate future risk.

PVEL’s field testing services can assess your project’s baseline health at module delivery and optimize post-installation performance.

Establish overall project health and mitigate future risk.

PVEL’s field testing services can assess your project’s baseline health at module delivery and optimize post-installation performance.

Evaluate the health of your modules with Field EL

Evaluate the health of your modules with Field EL

PVEL’s Field electroluminescence (EL) imaging services offer comprehensive solutions for understanding the health of your PV modules, diagnosing solar plant underperformance, and assessing the damage caused by force majeure events. EL images reveal cell-level damage and defects that are otherwise invisible to the human eye.

Illuminate the damage to your modules

PVEL’s streamlined EL imaging and analysis processes deliver fast, reliable, and cost-effective results.

EL technology relies on the same principle as a light-emitting diode (LED) to identify module damages. A radiative recombination of carriers is injected into a solar module causing light to be emitted and captured by an EL image.

The amount of light that radiates from each region of the module is proportional to its voltage potential, so inactive regions appear dark on EL images.

Field EL imaging can detect:

- Cell cracks and manufacturing defects

- Shipping and handling damage

- Mismatch and heat stress

- Potential-induced degradation (PID)

- Light- and elevated temperature-induced degradation (LETID)

Illuminate the damage to your modules

PVEL’s streamlined EL imaging and analysis processes deliver fast, reliable, and cost-effective results.

EL technology relies on the same principle as a light-emitting diode (LED) to identify module damages. A radiative recombination of carriers is injected into a solar module causing light to be emitted and captured by an EL image.

The amount of light that radiates from each region of the module is proportional to its voltage potential, so inactive regions appear dark on EL images.

Field EL imaging can detect

- Cell cracks and manufacturing defects

- Shipping and handling damage

- Mismatch and heat stress

- Potential-induced degradation (PID)

- Light- and elevated temperature-induced degradation (LETID)

What is the right tool for my project?

Drone EL Services

- Highest throughput option for a comprehensive assessment of module array health

- Can be used to assist with warranty and insurance claims in the event of serial module defects or damage

- Best tool for scanning large areas of arrays that have been damaged by extreme weather events

- Provides powerful insights for the due diligence during solar asset transfers

Module Acceptance

- To verify modules have not been damaged in transit before acceptance at the project site

- Uses a statistically significant sample from every week’s delivery

- Recurring service throughout the delivery schedule of a project

Daytime Field EL / Post-Construction Acceptance

- To verify the health of the array during or after commissioning

- Can be used for construction acceptance during hand-off from EPC to asset owner

- Serves as a baseline for module array health prior to extreme weather events

- Typically completed on a statistically significant sample rather than the entire site

Advantages of PVEL’s Field Testing

Efficient, flexible scoping

Field EL images can be taken for all modules or a sample size targeting particular areas in accordance with ISO 2859 sampling guidelines. Testing can occur during regular daytime working hours, or leverage our proprietary nighttime Drone EL solution.

Accurate and Fast Imaging Results

Delivery-acceptance testing is performed as modules are removed from the packaging before installation. Post-installation EL imaging is conducted onsite while modules remain installed.

Proprietary techniques

PVEL’s leading PV scientists have developed a unique methodology that uses artificial intelligence (AI) to efficiently and consistently produce accurate, data-driven damage assessments.

When should you conduct field EL image testing?

1. At PV module delivery acceptance.

Determine if PV modules were damaged during manufacturing and/or shipment.

2. At site acceptance/EPC hand-off.

Establish baseline project health for future warranty or insurance and claims, and determine if installation damage occurred.

3. After force majeure events.

Quantify PV module damage to submit accurate, comprehensive claims for natural disasters, such as hail, high winds, fire, and hurricanes.

4. When system underperformance occurs.

Guide repairs and maintenance by determining if PV modules are the root cause of underperformance.

5. During due diligence for project sales.

Validate that PV modules are in good working order prior to project acquisition.

Maximize the ROI of your PV modules

Field EL imaging helps you maximize ROI by:

- Validating the baseline module health at delivery and post-installation.

- Remedying system underperformance.

- Fully assessing damages for insurance claims.

Learn more about field testing

Leverage our expertise in field EL images to assess the health of your PV modules. Contact us for a consultation.